Factors Affecting Washing Efficiency

(1) Washing Temperature

The solubility of impurities such as MgCl2, MgSO4, and CaSO4 in raw salt varies with washing temperature.The solubility of CaSO4 decreases with increasing washing temperature, while the solubility of MgCl2 and MgSO4 increases with rising temperature. Therefore, increasing the washing temperature is beneficial for the dissolution of MgCl2 and MgSO4 and improves the washing efficiency for these impurities.

(2) Quality of Washing Solution

The quality of the washing solution is directly related to the quality of the crushed and washed salt. The washing solution is a complex solution containing various salts, and the solubility of each salt is influenced by the presence of other salts. The solubility of MgCl2, MgSO4, and CaSO4 all decrease to varying degrees with increasing concentration of the washing solution. The solubility of MgCl2 and MgSO4 decreases significantly with increasing Mg2+ concentration in the washing solution. Therefore, in the production of crushed and washed salt, the Mg2+ concentration in the washing solution should be strictly controlled. For example, some washed salt plants control the standard as Mg2+ ≤ 1.7 g/100 mL in the washing solution.

In addition to controlling the quality of the washing solution, spraying a small amount of fresh water in the centrifuge to wash the salt is also an effective measure to improve the quality of the washed salt.

(3) Solid-Liquid Contact Area

The larger the solid-liquid contact area, the better the removal effect of soluble impurities. Therefore, there needs to be an appropriate solid-to-liquid ratio between the salt and the washing solution. A high solid-to-liquid ratio is not conducive to sufficient contact between the salt and the washing solution, while a low solid-to-liquid ratio does not significantly increase washing efficiency and instead increases the amount of circulating brine, resulting in increased power consumption and salt overflow losses. Generally, the solid-to-liquid ratio (volume ratio) for washed salt is (1:3) to (1:4).

The contact area between raw salt and brine is related to the particle size of the raw salt. The smaller the particle size of the salt, the larger the surface area per unit mass of salt, and the better the washing effect. Therefore, in the process of washing raw salt, the particle size of the raw salt is reduced through crushing to increase the surface area of the salt crystals, allowing the impurities and mother liquor trapped inside the crystals to be carried away by the washing solution to the greatest extent. However, when the particle size of the raw salt is too small, the crystals carry more mother liquor, which instead reduces the quality of the washed salt. Therefore, the particle size of the salt should be determined based on the dewatering capacity to achieve the best washing effect. The optimal washing effect is achieved with a salt particle size of 0.6 to 1.2 mm. In addition, enhancing stirring is beneficial for sufficient solid-liquid contact and can also improve washing efficiency.

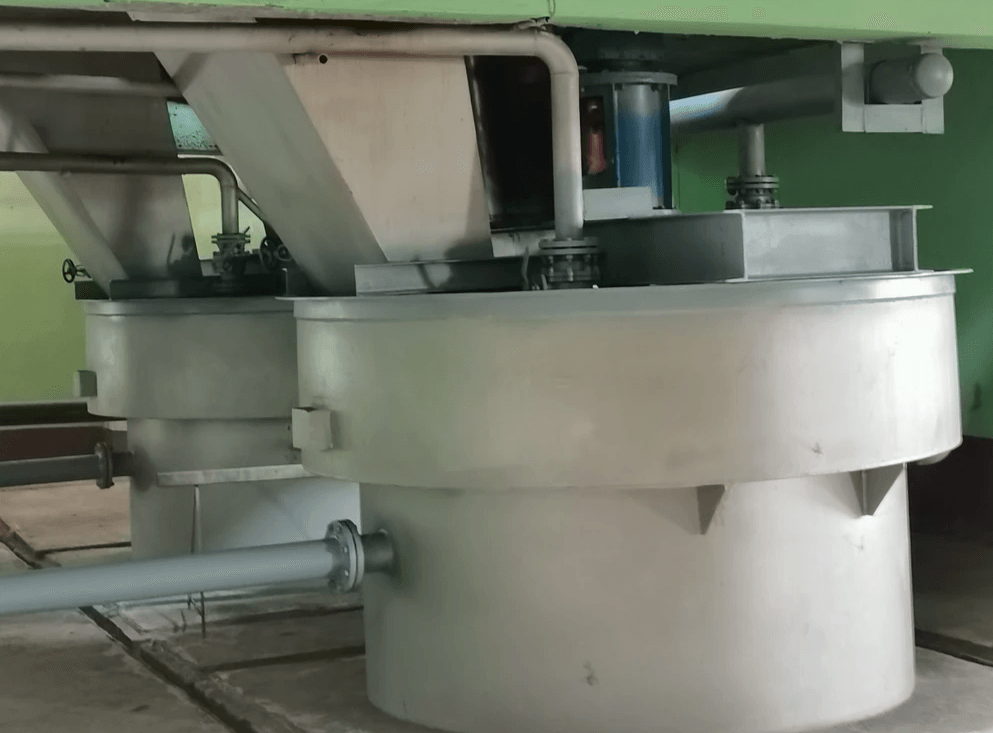

(Stirred Tank, Mixing Tank)