Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Salt Refining Processes

Providing comprehensive solutions for each process of your salt production including wastewater treatment.

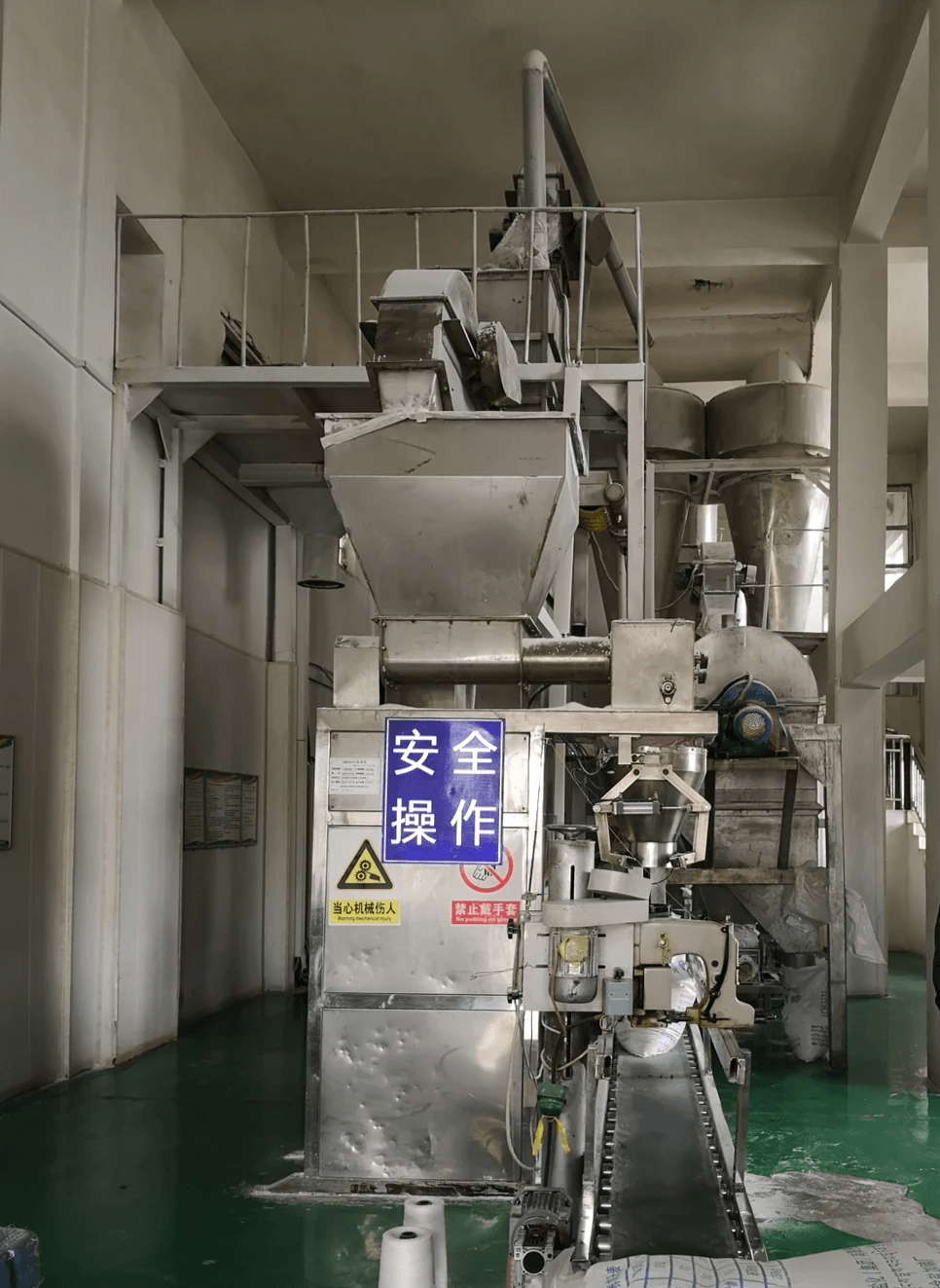

The Processes of Mechanical Salt Refinery

Simple operation, stable running, much more investmetn and energy saving, and different combinations of equipment and technological adjustments can produce salt in different sizes, purities and applications.

Salt washing, crushing and impurity extraction are defined as mechanical salt refinery. The main idea is to crush large salt particles to expose impurities as much as possible and wash out impurities from the particle surface. Therefore, the salt produced also called the crushed and washed salt.

Combined the technologies of screw washing, stirred washing, countercurrent washing and roller crushing, impurities could be washed out effectively while reducing salt powder and salt loss.

After crushing and washing, the drying system drys salt to the desired moisture content, and the sieving system classifies particles of different sizes for different applications (cooking salt, table salt, industrial salt, etc.).

The final product salt is dry, white, shiny, and free-flowing.

Note:

- The PFD is for reference only.

- Based on the basic data and varying requirements of different plants, the process needs to be professionally customized and appropriately adjusted.

Application

- Producing salt with different particle sizes according to different needs.

- Making and ensuring even salt particle sizes for specific applications such as baking. Uniform salt particles guarantee consistent fermentation and texture control during the baking process.

- For solid raw salt (sea salt or lake salt)

Equipments Related

- Capacity: 1-100 tons per hour

- Operation Hours: 8000 hours per year

- Process: Continuous

- Material: SS316L or CS

- Controlling Panel: Cabinet/PLC/DCS

- Leading Time: 3-6 Months

- Installation and Commissioning: 2-4 Months

- Warranty: 1 Year

- Service: 24/7

Patents

- One Kind of Wet Material Discharging Mechanism for Centrifugal Dewatering Machine to Reduce Accumulation (Patent No.: ZL 2021 2 2227726.7)

- etc..

Interested in Balance Salt?

Feel free to call us or drop a line.

Select...

©2024-2025 Balance Salt