Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Salt Refining Processes

Providing comprehensive solutions for each process of your salt production including wastewater treatment.

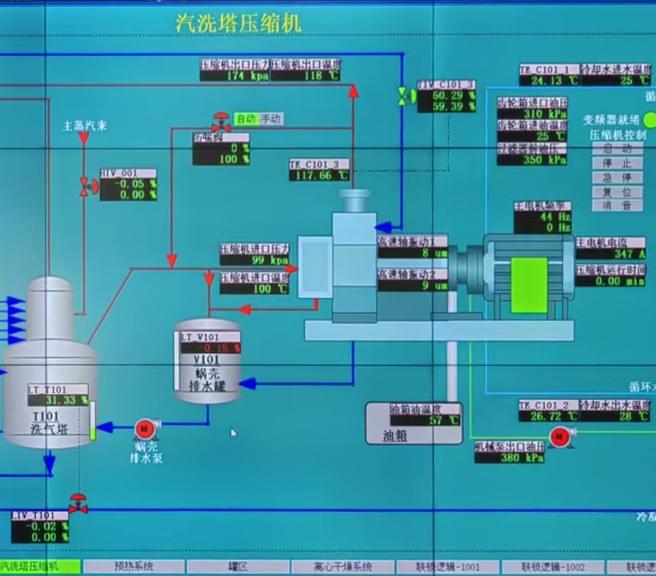

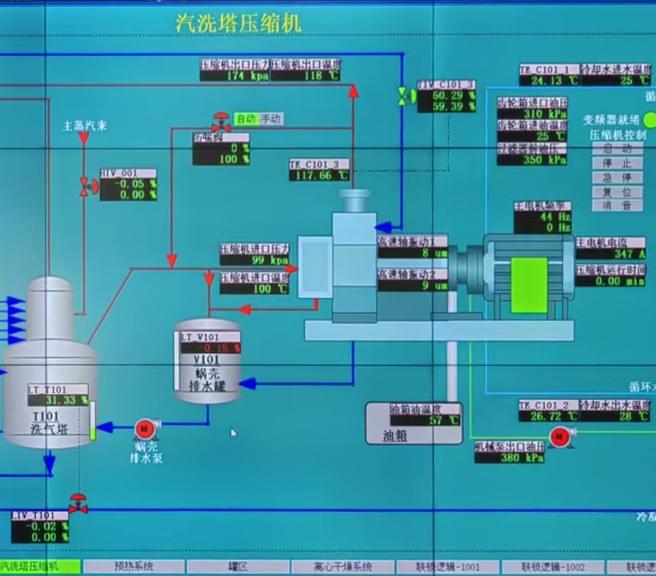

The Processes of MVR Salt Refinery

MVR is mechanical vapor recompression, which is more energy and operating costs saving, small footprint, less public works, less total investment in the project, reliable operation and high degree of automation, and no need to add fresh steam during production.

In mechanical vapor recompression, the secondary steam evaporated from the evaporator is adiabatically compressed by a mechanically driven compressor, increasing its pressure and temperature.

Therefore, the compressor also functions as a heat pump to add energy to the steam. That is, during its working process, the low-grade steam is adiabatically compressed by the compressor, increasing its temperature, pressure, and enthalpy, and then enters the heating chamber of the evaporator to condense and release heat, fully utilizing the latent heat of the secondary steam.

Except for the initial startup, the entire evaporation process does not require fresh steam.

Note:

- The PFD is for reference only.

- Based on the basic data and varying requirements of different plants, the process needs to be professionally customized and appropriately adjusted.

Application

- Evaporation, concentration, and crystallization of aqueous solutions in the industries such as Salt Refining, Sodium

Sulfate Refining, Food, Chemical Engineering, New Energy, etc. - Be widely used in wastewater treatment in the above industries.

- Especially suitable for where electricity prices are relatively cheap, while steam prices are is high price or supply is unstable.

Equipments Related

- Capacity: 0.5-100 tons per hour (a single set)

- Operation Hours: 8000 hours per year

- Process: Continuous

- Material: Titanium, 8367, DSS, SS316L, SS304 or CS

- Controlling Panel: DCS

- Leading Time: 4-6 Months

- Installation and Commissioning: 3-6 Months

- Warranty: 1 Year

- Service: 24/7

Patents

- One Kind of Baffle Entrainment Separator for Salt Refining (Patent No.: ZL 2021 2 2450261.1)

- One Kind of Dedusting Water Overflow Suppression Divice for Wet Dust Collector (Patent No.: ZL 2021 2 2276901.1)

- One Kind of Wet Material Discharging Mechanism for Centrifugal Dewatering Machine to Reduce Accumulation (Patent No.: ZL 2021 2 2227726.7)

- etc..

Interested in Balance Salt?

Feel free to call us or drop a line.

Select...

©2024-2025 Balance Salt