Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Salt Refining Processes

Providing comprehensive solutions for each process of your salt production including wastewater treatment.

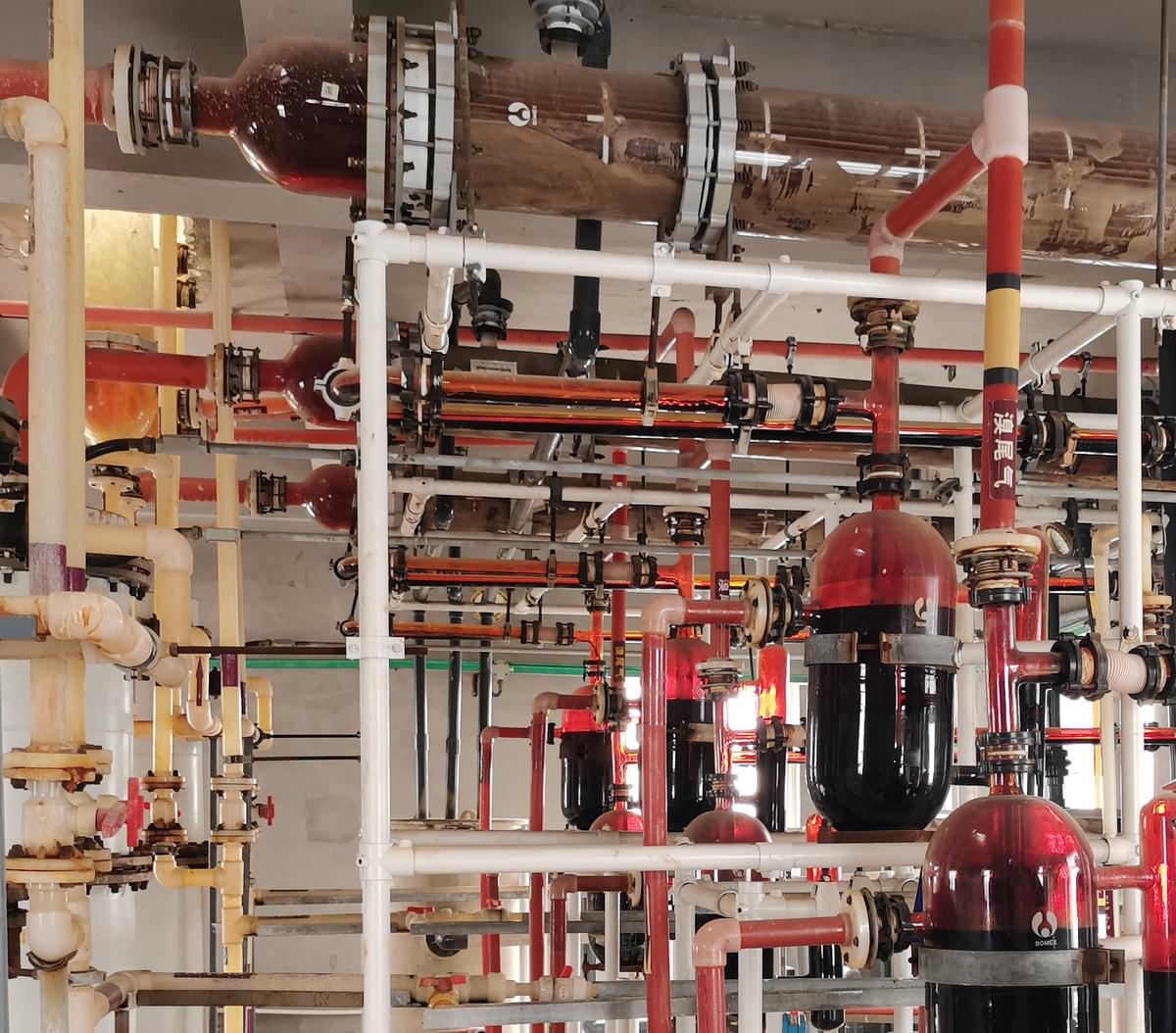

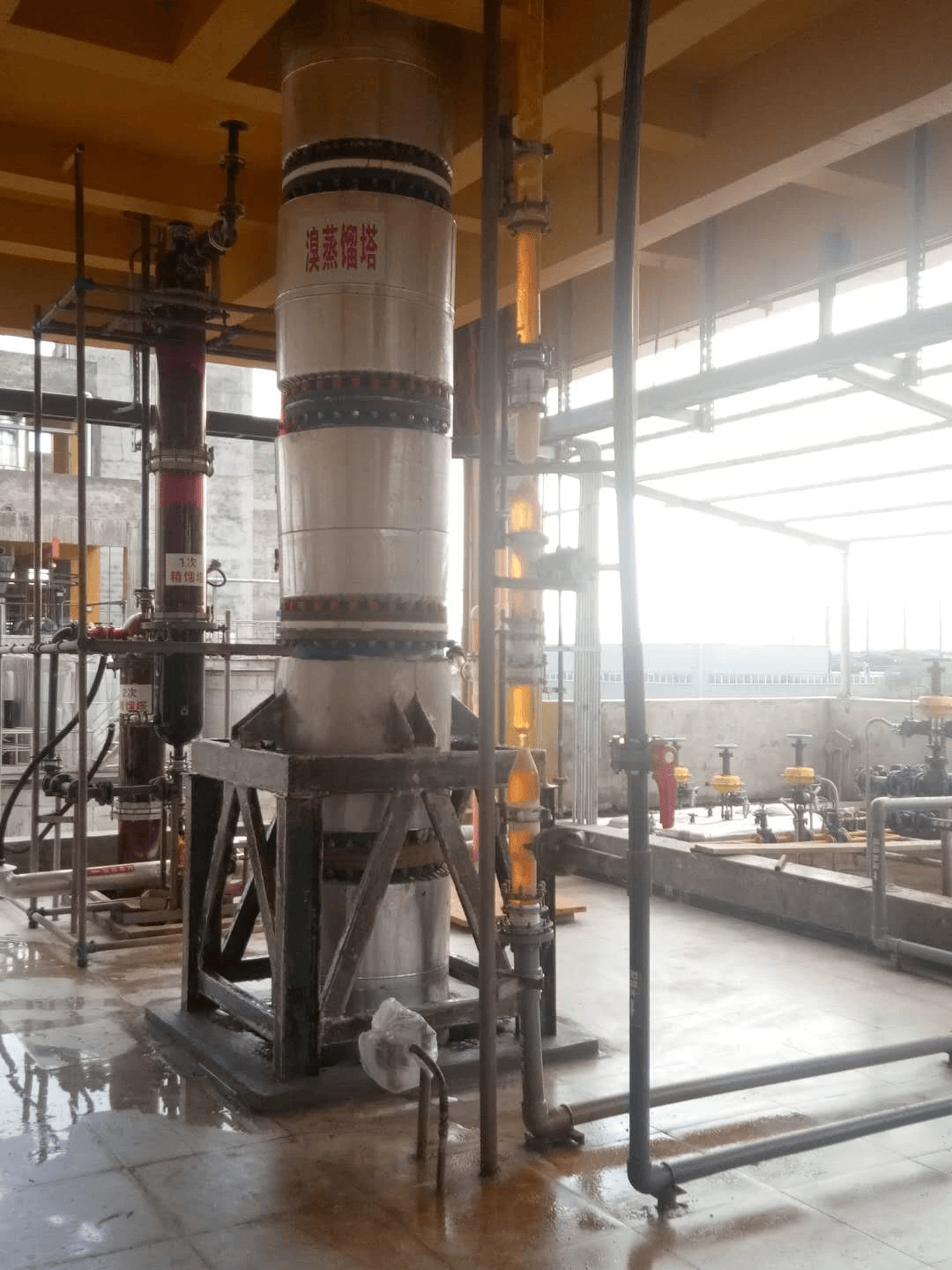

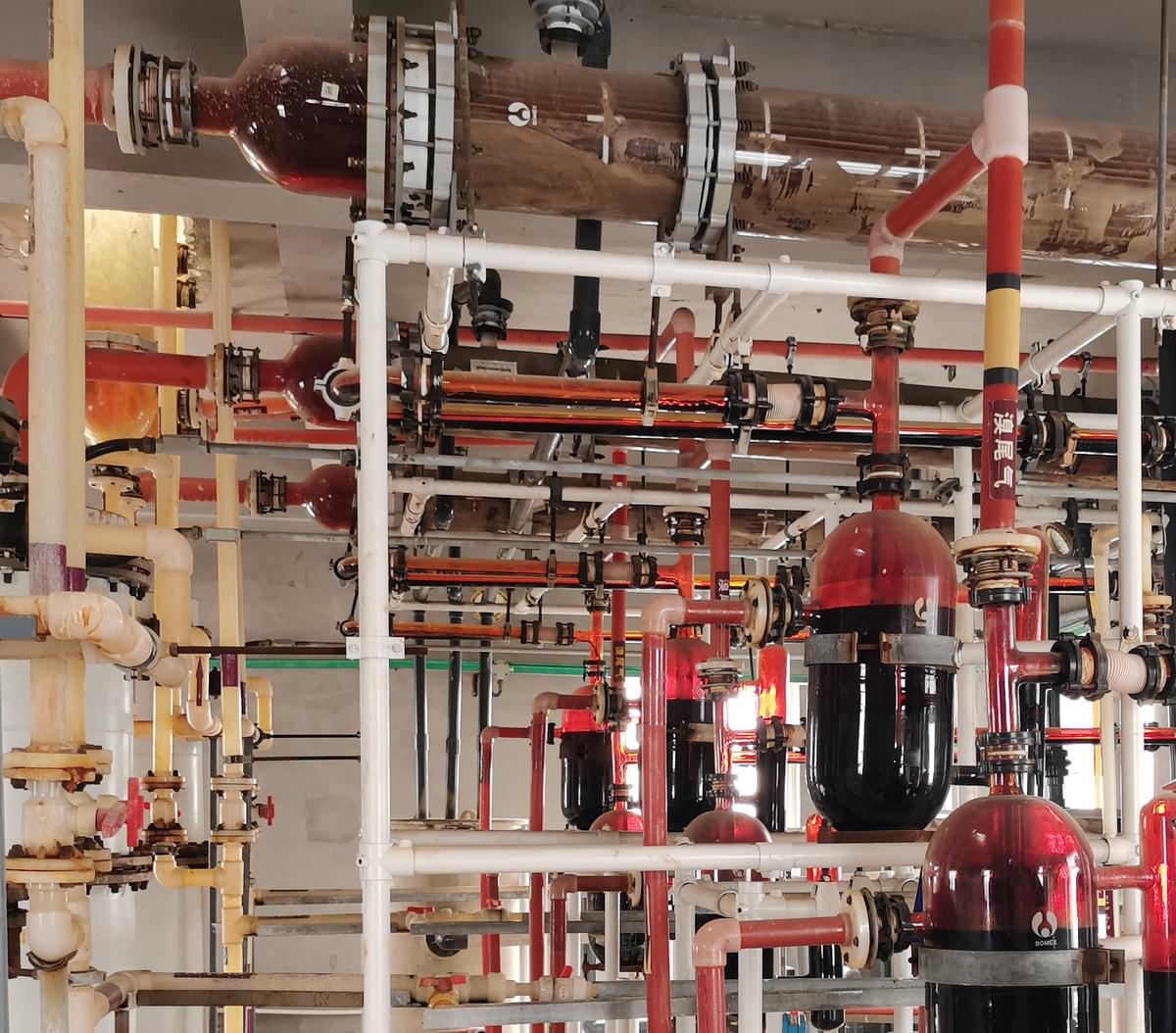

The Processes of Bromine Extraction

Adopting Air-blowing process, which is strong adaptability to raw materials, easy automatic control, stable and high quality products, good environmental durability and suitable for large-scale production.

The technical process mainly consists of two parts: bromine extraction process and bromine refinement process.

The bromine extraction process mainly includes several key stages: brominated brine acidification, chlorine oxidation, air blowing, and absorption.

The refinement process uses solution of hydrobromic acid from the completed liquid tank as the raw material for bromine refinement, and the main stages include oxidation distillation, condensation separation, acid washing and filling.

Note:

- The PFD is for reference only.

- Based on the basic data and varying requirements of different plants, the process needs to be professionally customized and appropriately adjusted.

Application

- Suitable for Low-concentration Brominated brine, such as seawater, underground brine, etc..

Equipments Related

- Capacity: 100-60,000 tons per year

- Process: Continuous

- Material: Carbon Steel with PTFE Liner, Ceramic, Glass and Fiber Glass

- Controlling Panel: Cabinet/PLC/DCS

- Leading Time: 3-6 Months

- Installation and Commissioning: 2-3 Months

- Warranty: 1 Year

- Service: 24/7

Patents

- One kind of Automatic System of Oxidation Process in Bromine Extraction by Steam Distillation (Patent No.: ZL 2021 2 2227726.7)

Interested in Balance Salt?

Feel free to call us or drop a line.

Select...

©2024-2025 Balance Salt