Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Salt Refining Processes

Providing comprehensive solutions for each process of your salt production including wastewater treatment.

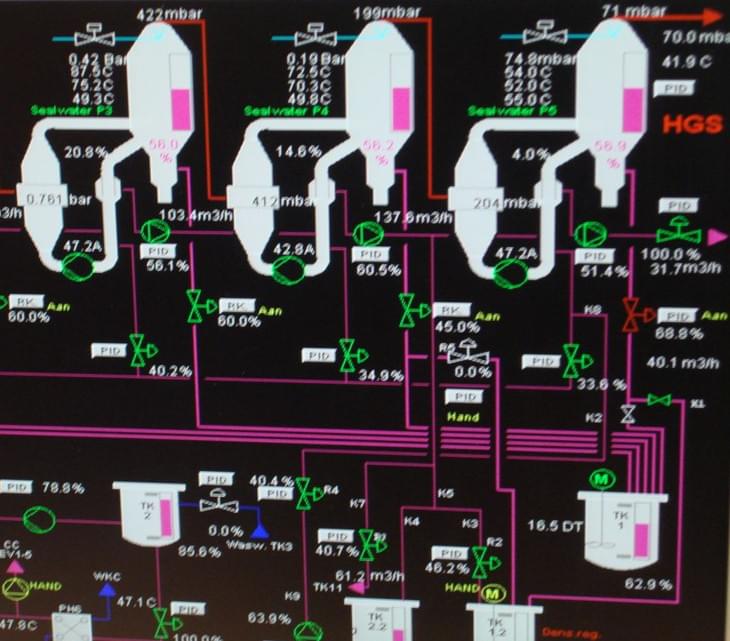

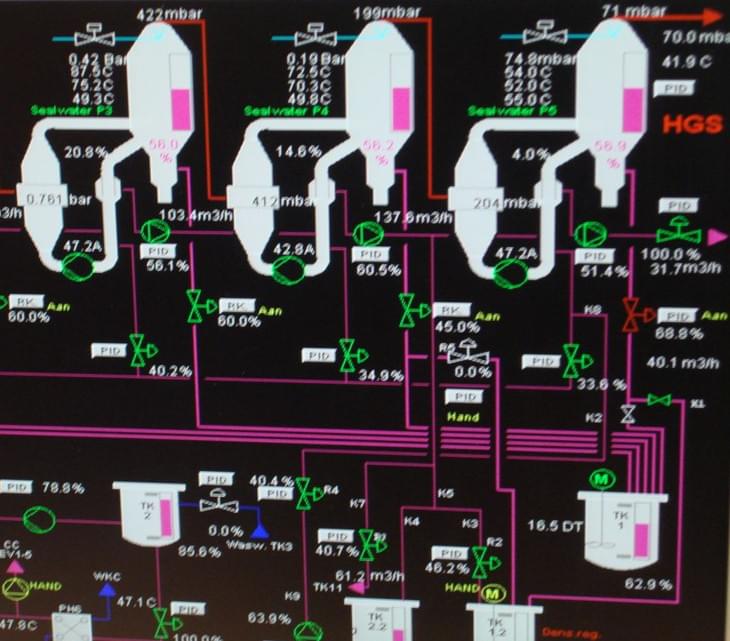

The Processes of Multi-effect Evaporation (ME) Salt Refinery

Multi-effect Evaporation has strong evaporation capacity, simple and stable operation, more energy and operating costs saving.

The multi-effect evaporation system is a series of evaporators connected in series, where the secondary steam from the previous effect is used as the heating steam for the next effect.

Except for the first effect, which uses fresh steam, all other effects utilize the secondary steam generated by the previous effect.

Only the secondary steam from the last effect requires a cooling medium for condensation.

Therefore, the multi-effect evaporation system not only significantly saves on the consumption of heating steam, but also significantly reduces the usage of cooling water.

Note:

- The PFD is for reference only.

- Based on the basic data and varying requirements of different plants, the process needs to be professionally customized and appropriately adjusted.

Application

- Evaporation, concentration, and crystallization of aqueous solutions in the industries such as Salt Refining, Sodium Sulfate Refining, Food, Chemical Engineering, New Energy, etc.

- Be widely used in wastewater treatment in the above industries.

- Especially suitable for where the steam price relatively low.

Equipment Related

- Capacity: 0.5-200 tons per hour

- Operation Hours: 8000 hours per year

- Process: Continuous

- Effects: 2-6, according to the design

- Material: Titanium, 8367, DSS, SS316L, SS304 or CS

- Controlling Panel: DCS

- Leading Time: 4-6 Months

- Installation and Commissioning: 3-6 Months

- Warranty: 1 Year

- Service: 24/7

Patents

- One Kind of Multi-effect Evaporation Facility for Salt Refining (Patent No.: ZL 2021 2 2419821.7)

- One Kind of Externally Heated Forced Circulation Evaporator Facility (Patent No.: ZL 2021 2 2322213.4)

- One Kind of Multi-direction Feeding Device for an Evaporation Tank (Patent No.: ZL 2021 2 2366506.2)

- One Kind of Wet Material Discharging Mechanism for Centrifugal Dewatering Machine to Reduce Accumulation (Patent No.: ZL 2021 2 2227726.7)

- etc..

Interested in Balance Salt?

Feel free to call us or drop a line.

Select...

©2024-2025 Balance Salt