Why do the evaporation chambers need to be progressively enlarged?

Do you notice that the diameters of the chambers of multi-effect plant increase progressively from one effect to the next?

Why is this the case?

Let's first examine the specific volume and cross-sectional velocity of the secondary steam in each effect.

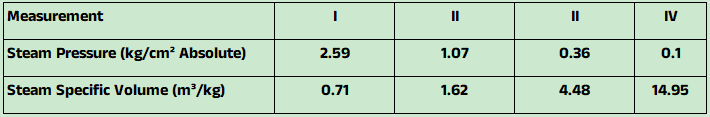

For instance, consider the following pressures and specific volumes for each effect:

From the above, it is evident that the specific volume of secondary steam (the volume occupied by each kilogram of steam) increases dramatically from one effect to the next, with the fourth effect being 21 times that of the first effect.

If the cross-sectional areas of all chambers were equal, and the evaporation water volume in each chamber did not differ significantly, the steam velocity would increase progressively from one effect to the next, potentially leading to the entrainment of brine droplets out of the evaporation chambers, resulting in liquid carryover or material loss.

Therefore, to keep the changes in steam velocity within a manageable range, it is necessary to progressively increase the diameters of the evaporation chambers from one effect to the next.

However, this design approach can complicate manufacturing (and maintenance), design, and civil engineering aspects.

The specific design approach should be determined based on actual conditions.

P.S. Balance Salt has participated in and completed nearly 300 projects of salt refining. We have rich experience in fault diganosis of the process and production of salt refining. Any questions regarding salt refining, welcome consulting us.