Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Balance Salt Refinery Technical Services & Engineering Co., Ltd.

Your trusted partner for turnkey projects of new built and remodeling salt plants.

- …

Salt Refining Processes

Providing comprehensive solutions for each process of your salt production including wastewater treatment.

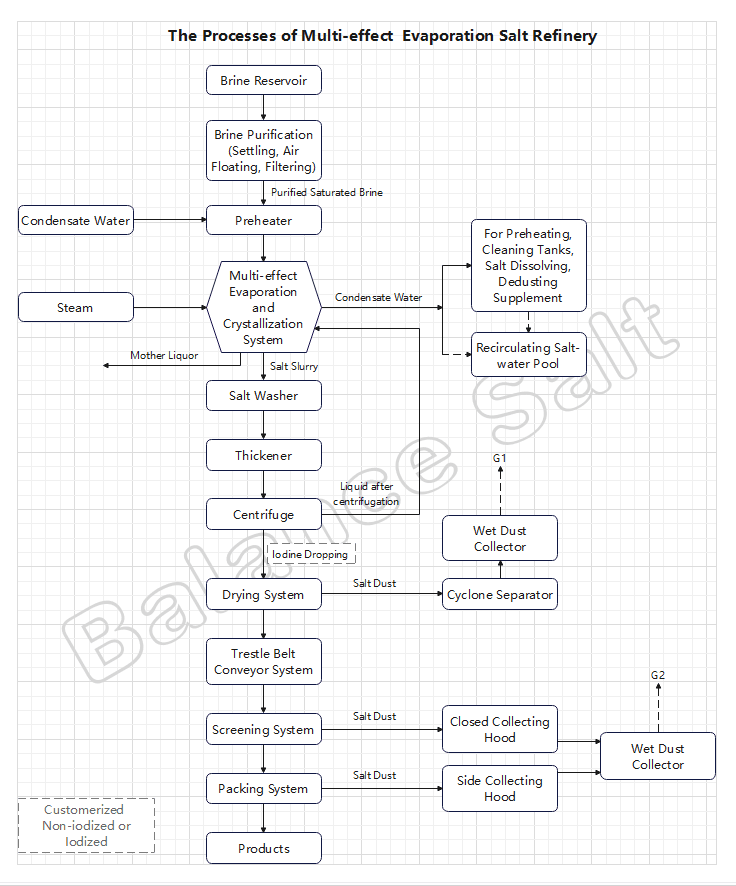

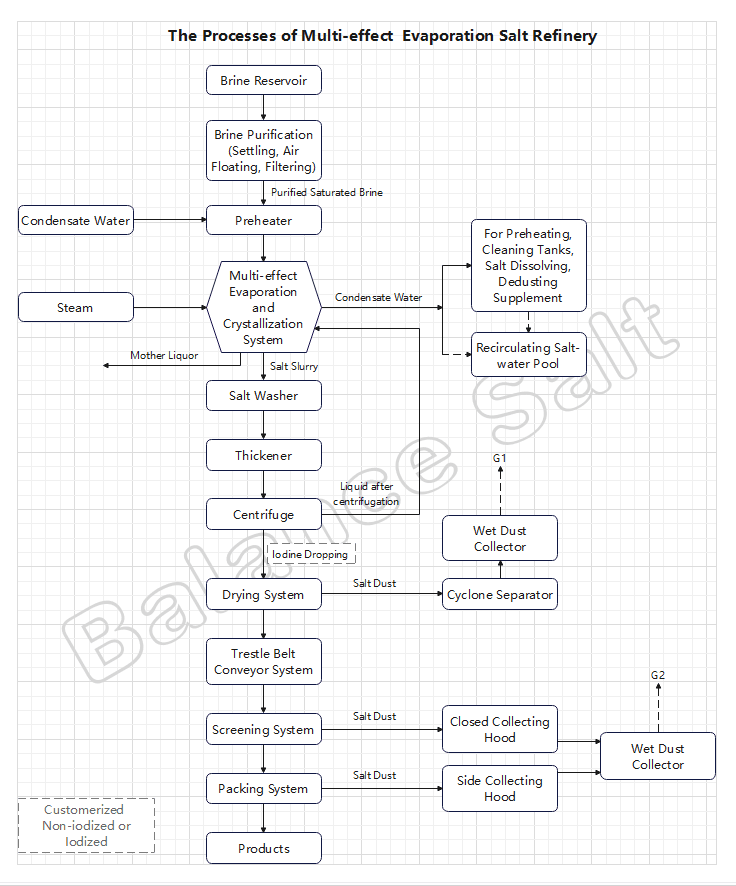

The Processes of Multi-effect Evaporation (ME) Salt Refinery

Multi-effect Evaporation has strong evaporation capacity, simple and stable operation, more energy and operating costs saving.

The multi-effect evaporation system is a series of evaporators connected in series, where the secondary steam from the previous effect is used as the heating steam for the next effect.

Except for the first effect, which uses fresh steam, all other effects utilize the secondary steam generated by the previous effect.

Only the secondary steam from the last effect requires a cooling medium for condensation.

Therefore, the multi-effect evaporation system not only significantly saves on the consumption of heating steam, but also significantly reduces the usage of cooling water.

Application

- Evaporation, concentration, and crystallization of aqueous solutions in the industries such as Salt Refinery, Nitrate Refinery, Food, Chemical Engineering, New Energy, etc.

- Be widely used in wastewater treatment in the above industries.

- Especially suitable for where the steam price relatively low.

Equipment Related

- Capacity: 10000 tons - 1.5 million tons/year

- Process: Continuous

- Effects: 2-6, according to the design

- Material: Titanium, DSS, SS316L or SS304

- Controlling Panel: DCS

- Leading Time: 3-6 Months

- Installation and Commissioning: 1-2 Months

- Warranty: 1 Year

- Service: 24/7

Patents

- One Kind of Multi-effect Evaporation Facility for Salt Refining (Patent No.: ZL 2021 2 2419821.7)

- One Kind of Externally Heated Forced Circulation Evaporator Facility (Patent No.: ZL 2021 2 2322213.4)

- One Kind of Multi-direction Feeding Device for an Evaporation Tank (Patent No.: ZL 2021 2 2366506.2)

- One Kind of Wet Material Discharging Mechanism for Centrifugal Dewatering Machine to Reduce Accumulation (Patent No.: ZL 2021 2 2227726.7)

- etc..

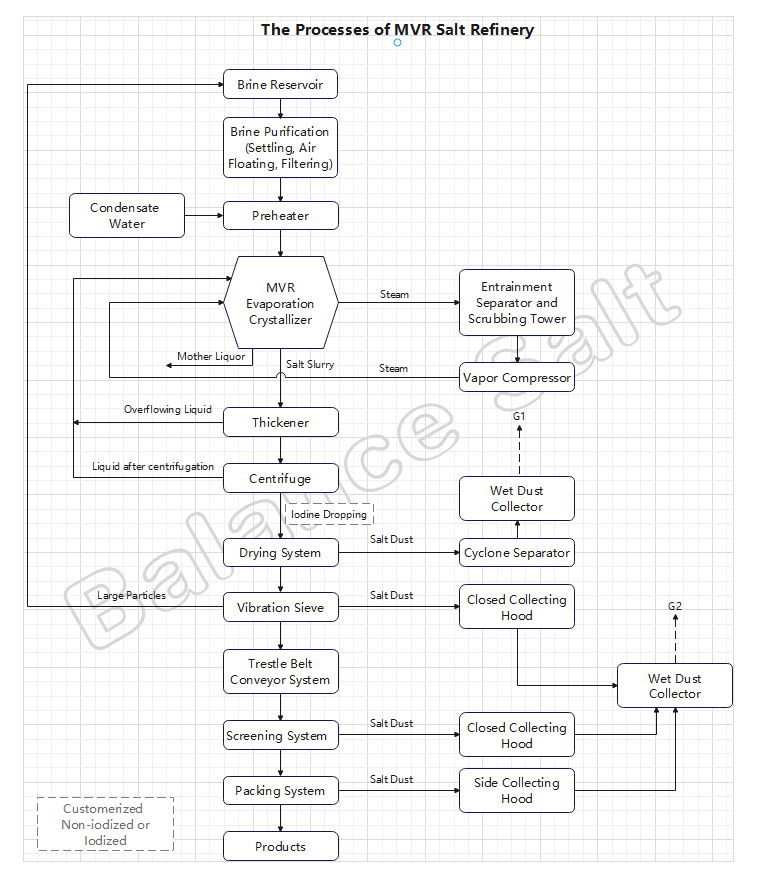

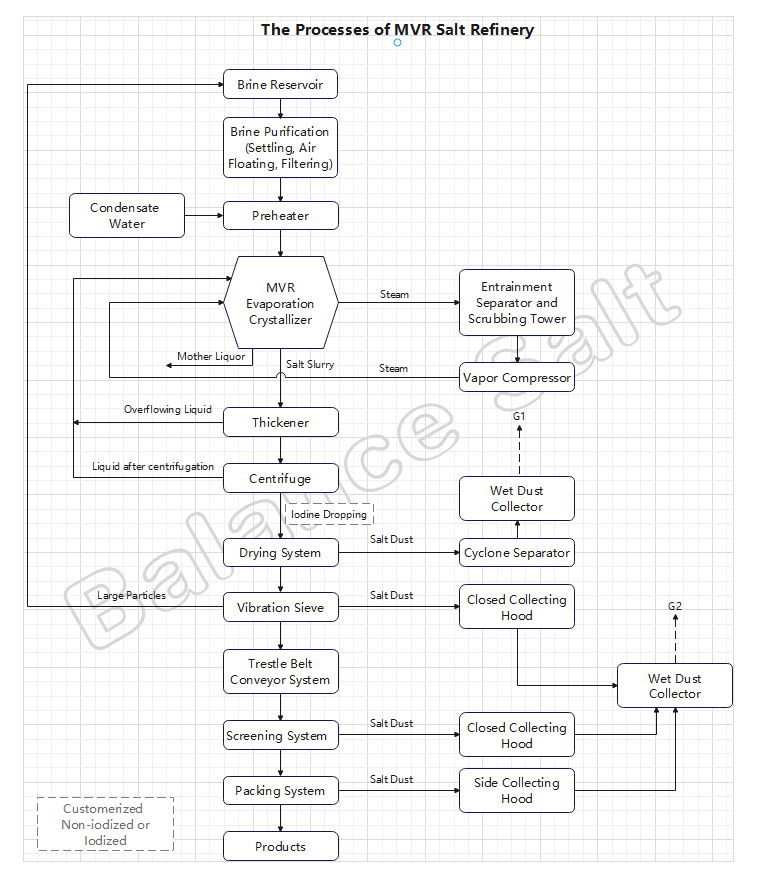

The Processes of MVR Salt Refinery

MVR is mechanical vapor recompression, which is more energy and operating costs saving, small footprint, less public works, less total investment in the project, reliable operation and high degree of automation, and no need to add fresh steam during production.

In mechanical vapor recompression, the secondary steam evaporated from the evaporator is adiabatically compressed by a mechanically driven compressor, increasing its pressure and temperature.

Therefore, the compressor also functions as a heat pump to add energy to the steam. That is, during its working process, the low-grade steam is adiabatically compressed by the compressor, increasing its temperature, pressure, and enthalpy, and then enters the heating chamber of the evaporator to condense and release heat, fully utilizing the latent heat of the secondary steam.

Except for the initial startup, the entire evaporation process does not require fresh steam.

Application

- Evaporation and crystallization of materials with a wide range of evaporation capacity, heat sensitivity or high viscosity.

- Evaporation and crystallization of low-concentration wastewater that is prone to scaling.

- Especially suitable for where electricity prices are relatively cheap, while steam prices are is high price or supply is unstable.

Equipments Related

- Capacity: 50000 tons - 1.5 million tons/year

- Process: Continuous

- Material: Titanium, DSS, SS316L or SS304

- Controlling Panel: DCS

- Leading Time: 3-6 Months

- Installation and Commissioning: 1-2 Months

- Warranty: 1 Year

- Service: 24/7

Patents

- One Kind of Baffle Entrainment Separator for Salt Refining (Patent No.: ZL 2021 2 2450261.1)

- One Kind of Dedusting Water Overflow Suppression Divice for Wet Dust Collector (Patent No.: ZL 2021 2 2276901.1)

- One Kind of Wet Material Discharging Mechanism for Centrifugal Dewatering Machine to Reduce Accumulation (Patent No.: ZL 2021 2 2227726.7)

- etc..

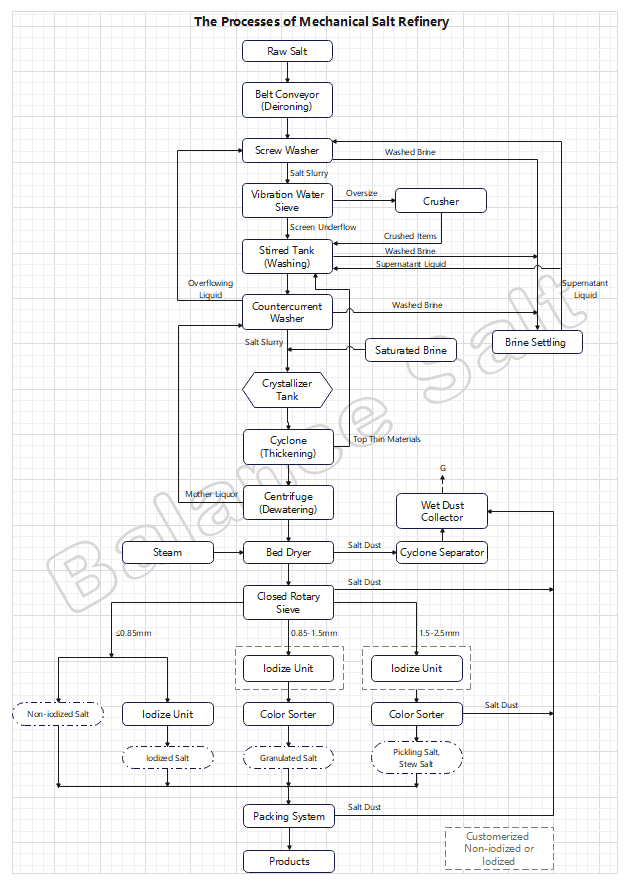

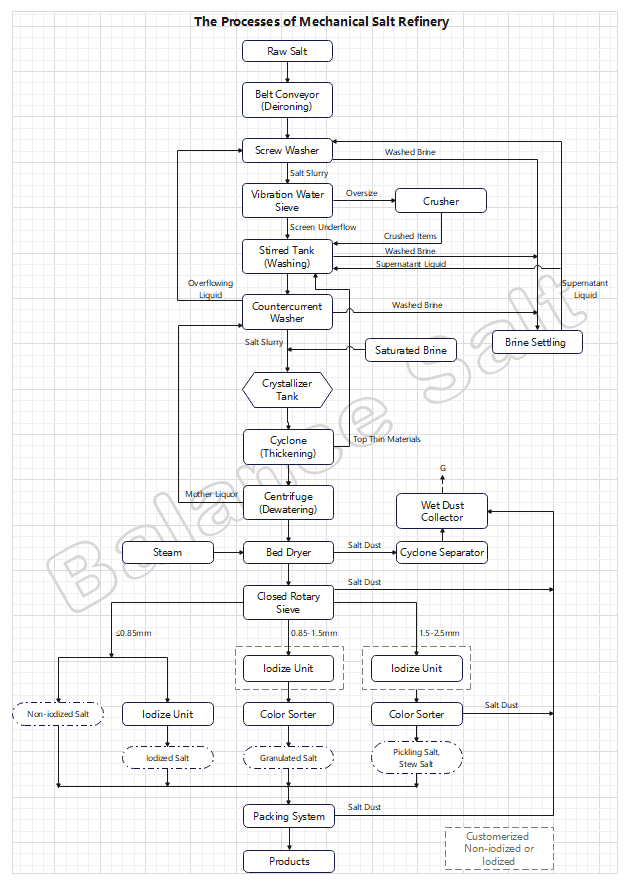

The Processes of Mechanical Salt Refinery

Simple operation, stable running, much more energy saving, and different combinations of equipment and technological adjustments can produce salt in different sizes, purities and applications.

Salt washing, crushing and impurity extraction are defined as mechanical salt refinery. The main idea is to crush large salt particles to expose impurities as much as possible and wash out impurities from the particle surface.

Combined the technologies of screw washing, stirred washing, countercurrent washing and roller crushing, impurities could be washed out effectively while reducing salt powder and salt loss.

After crushing and washing, the drying system drys salt to the desired moisture content, and the sieving system classifies particles of different sizes for different applications (cooking salt, table salt, industrial salt, etc.).

The final product salt is dry, white, shiny, and free-flowing.

Application

- Producing salt with different particle sizes according to different needs.

- Making and ensuring even salt particle sizes for specific applications such as baking. Uniform salt particles guarantee consistent fermentation and texture control during the baking process.

Equipments Related

- Capacity: 1-100 tons/hour

- Process: Continuous

- Material: SS316L

- Controlling Panel: Cabinet/PLC/DCS

- Leading Time: 3-6 Months

- Installation and Commissioning: 1-2 Months

- Warranty: 1 Year

- Service: 24/7

Patents

- One Kind of Wet Material Discharging Mechanism for Centrifugal Dewatering Machine to Reduce Accumulation (Patent No.: ZL 2021 2 2227726.7)

- etc..

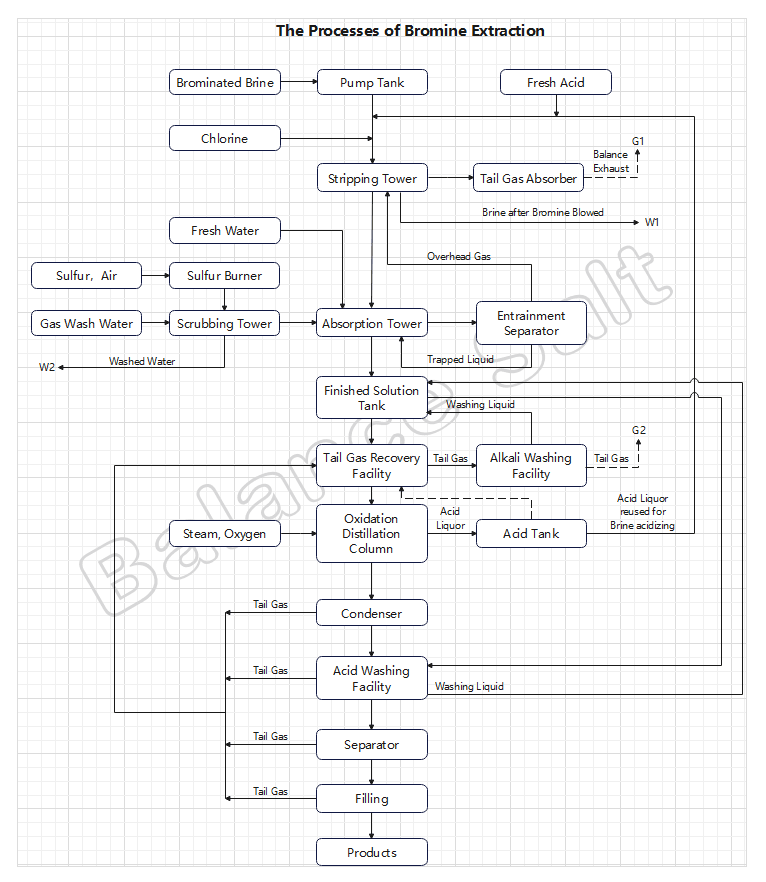

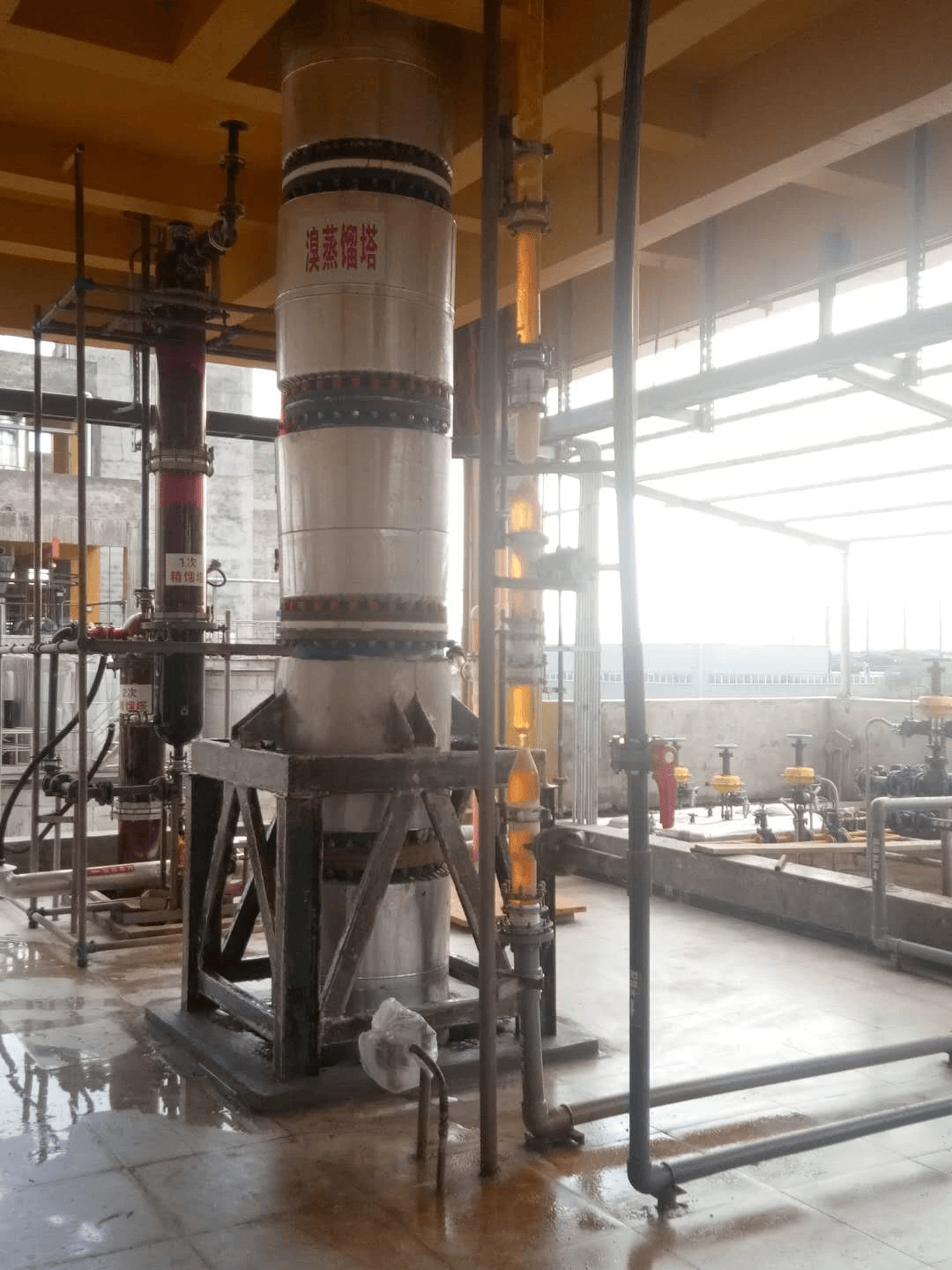

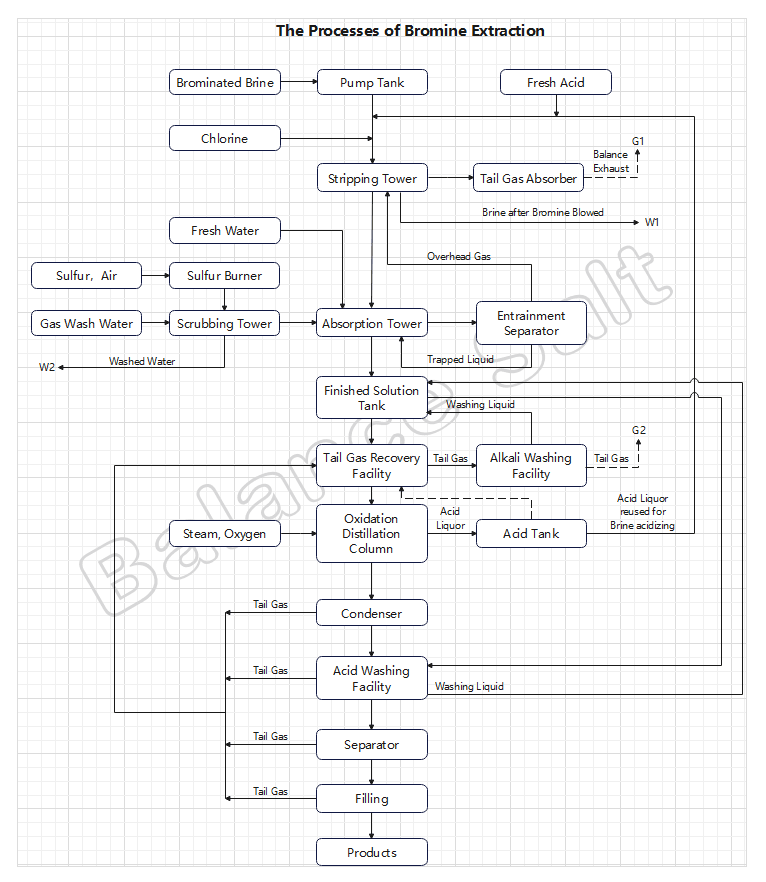

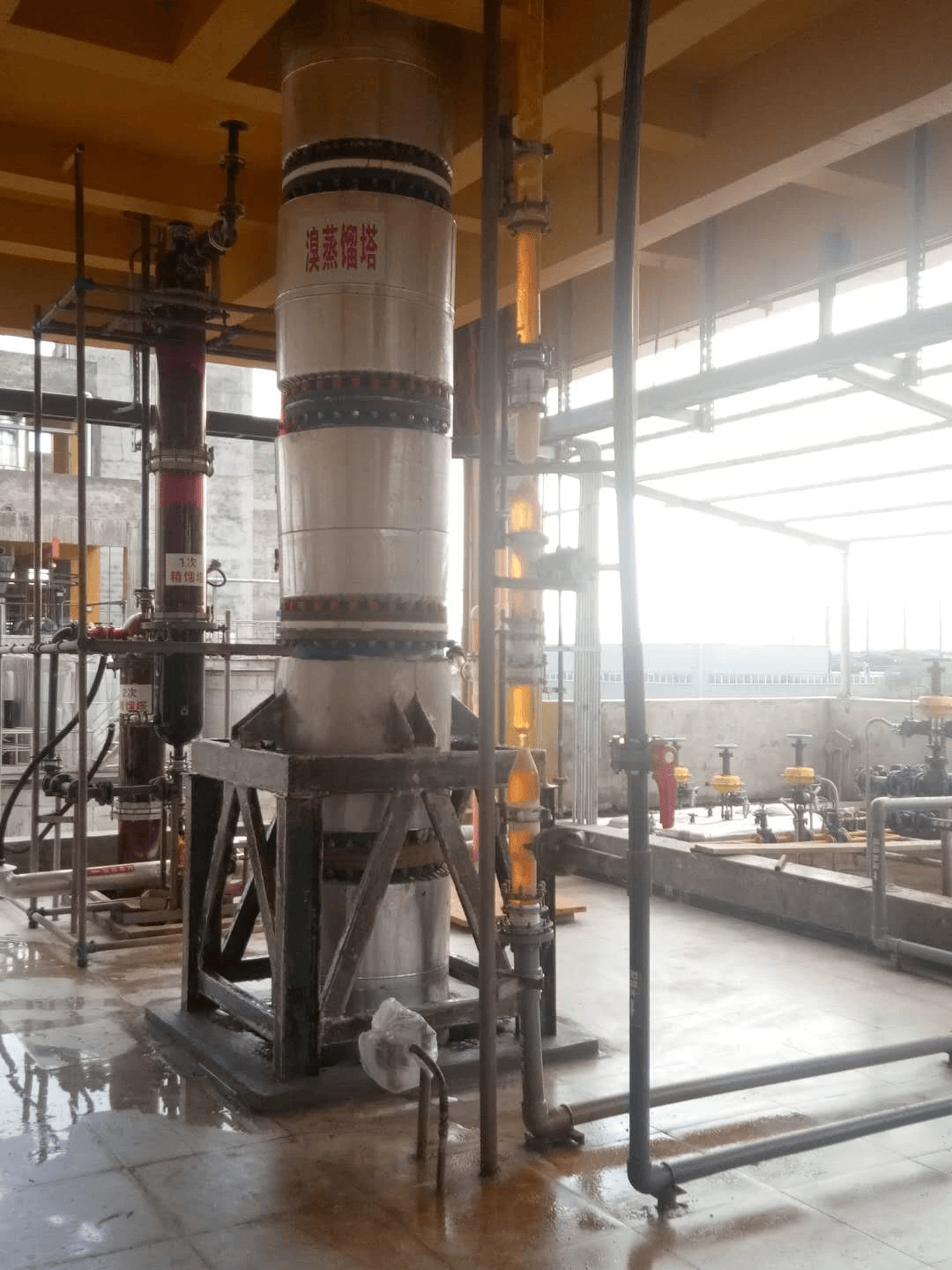

The Processes of Bromine Extraction

Adopting Air-blowing process, which is strong adaptability to raw materials, easy automatic control, stable and high quality products, good environmental durability and suitable for large-scale production.

The technical process mainly consists of two parts: bromine extraction process and bromine refinement process.

The bromine extraction process mainly includes several key stages: brominated brine acidification, chlorine oxidation, air blowing, and absorption.

The refinement process uses solution of hydrobromic acid from the completed liquid tank as the raw material for bromine refinement, and the main stages include oxidation distillation, condensation separation, acid washing and filling.

Application

- Suitable for Low-concentration Brominated brine, such as seawater, underground brine, etc..

Equipments Related

- Capacity: 100 tons-60,000 tons/year

- Process: Continuous

- Material: Carbon Steel with PTFE Liner, Ceramic, Glass and Fiber Glass

- Controlling Panel: Cabinet/PLC/DCS

- Leading Time: 3-6 Months

- Installation and Commissioning: 1-2 Months

- Warranty: 1 Year

- Service: 24/7

Patents

- One kind of Automatic System of Oxidation Process in Bromine Extraction by Steam Distillation (Patent No.: ZL 2021 2 2227726.7)

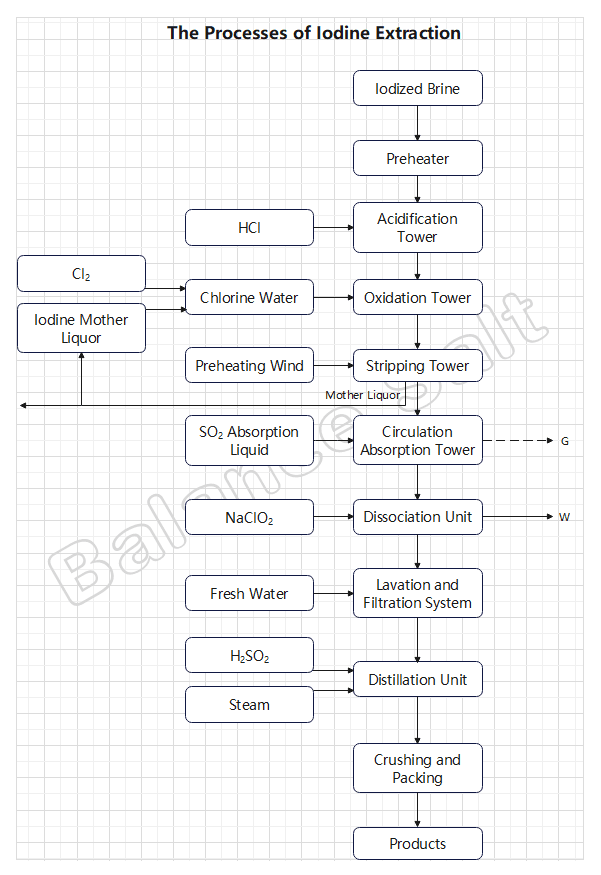

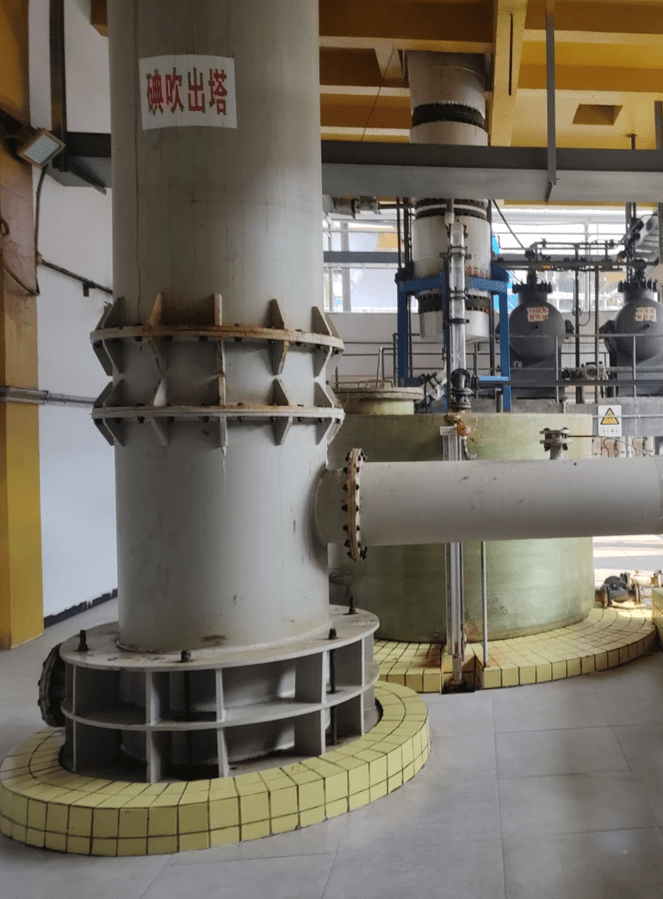

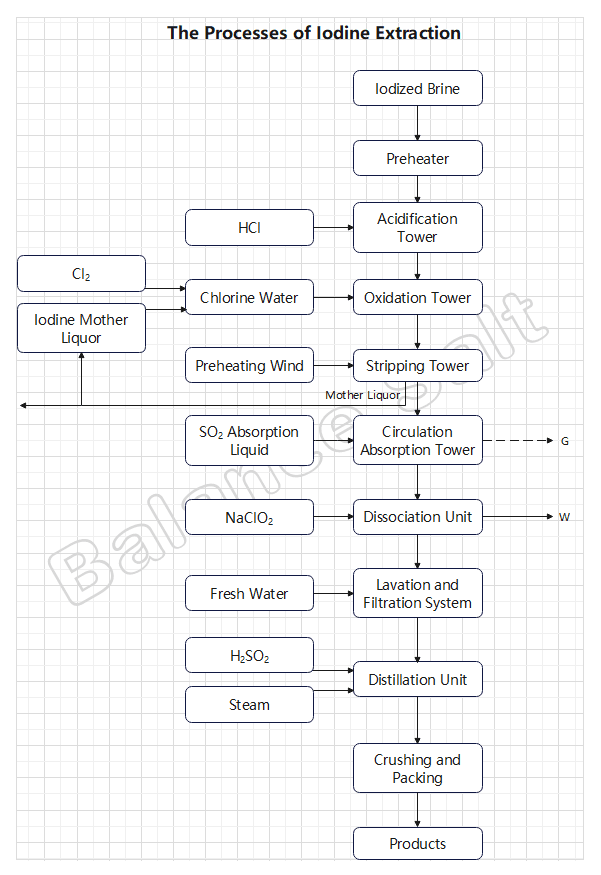

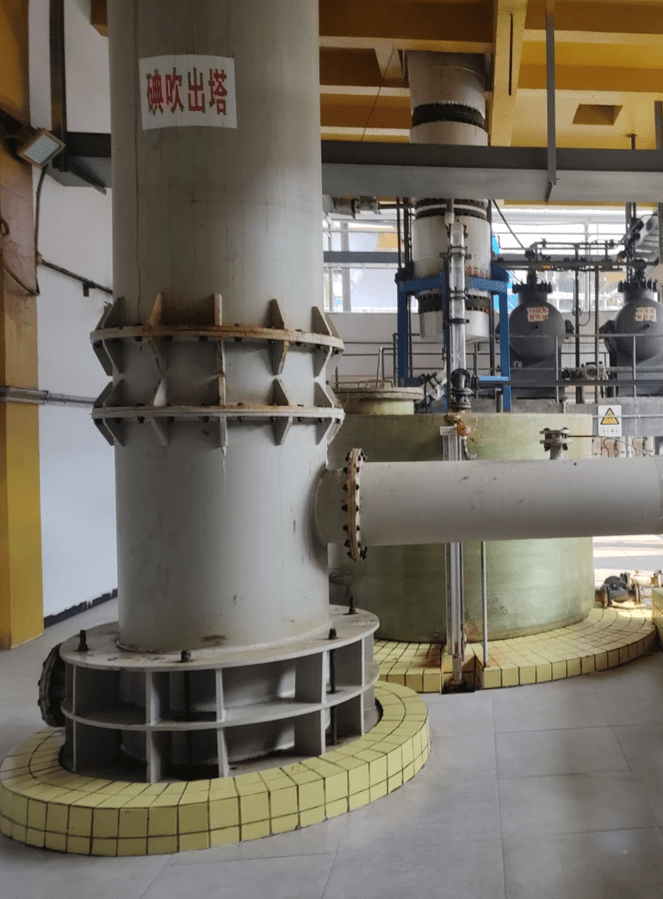

The Processes of Iodine Extraction

Adopting Air-blowing process, which has high extraction efficiency, simple and stable operation, easy automatic control, and low operation costs.

The technical process mainly consists of two parts: iodine extraction process and iodine refinement process.

The iodine extraction process mainly includes several key stages: iodized brine acidification, chlorine oxidation, air blowing, and absorption.

The refinement process uses the absorption liquid from circulation absorption tower as the raw material for iodine refinement, and the main stages include dissociation, lavation and filtration, steam distillation, and crushing and packing.

Application

- Suitable for different concentration of iodine-containing brine, especially for the treatment of low concentration brine.

Equipments Related

- Capacity: 1-100 tons/year

- Process: Continuous

- Material: Fiber Glass, PVC and PP

- Controlling Panel: Cabinet/PLC/DCS

- Leading Time: 3-6 Months

- Installation and Commissioning: 1-2 Months

- Warranty: 1 Year

- Service: 24/7

Interested in Balance Salt?

Feel free to call us or drop a line.

Select...

©2024-2025 Balance Salt